Researchers from the Built Environment Research Group at the Illinois Institute of Technology have conducted a study aiming to test the effectiveness of an enclosed chamber and HEPA filtration in reducing UFP and VOC emissions. Tiertime’s UP BOX+ and UP Fila ABS were the products used in the research.

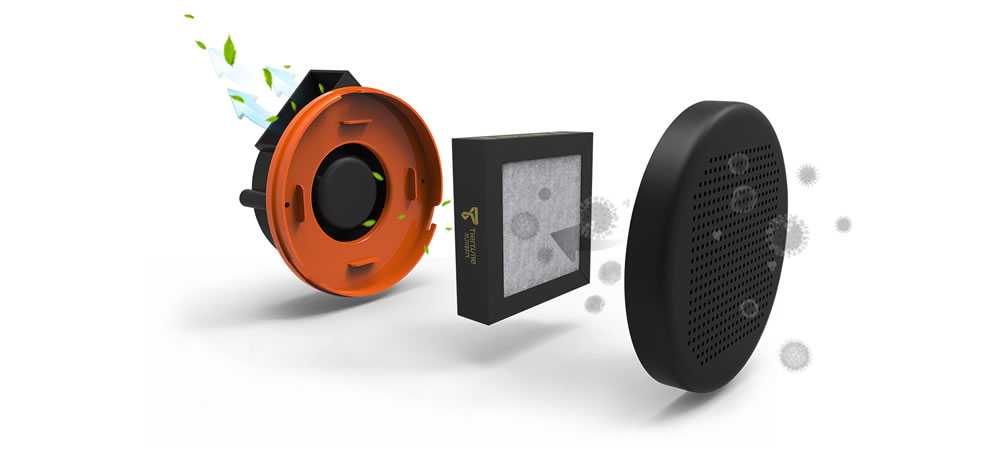

Intense concentrations of Ultrafine particles (UFP) can have a negative impact on people’s health and possibly trigger adverse reactions in individuals with various pulmonary disorders. According to the report, FFF 3D printer UFP emissions can be reduced at a rate of 74 percent with an enclosed build chamber. This reduction is enhanced by a HEPA filter, improving to 91 percent.

The group published the following chart demonstrating the maximum UFP concentration with HEPA filtration was 5.0E+03, which is more than 90% lower than other 3D printers tested.

Volatile Organic Compounds (VOC) are harmful chemical vapors produced when operating a 3D printer. According to the report, the total VOC generated by an UP BOX printing with ABS is 10.3. Based on previous studies done by the same researchers, it is a lower rate than other 3D printers tested with ABS.

An enclosed 3D printer design is crucial to user health. Built-in HEPA filtration with activated carbon can play a significant role in reducing harmful airborne particulates. These are standard features in the UP BOX+ and UP mini 2, making them the safe solution for printing with ABS in an office, classroom, or home.

An enclosed 3D printer design is crucial to user health. Built-in HEPA filtration with activated carbon can play a significant role in reducing harmful airborne particulates. These are standard features in the UP BOX+ and UP mini 2, making them the safe solution for printing with ABS in an office, classroom, or home.