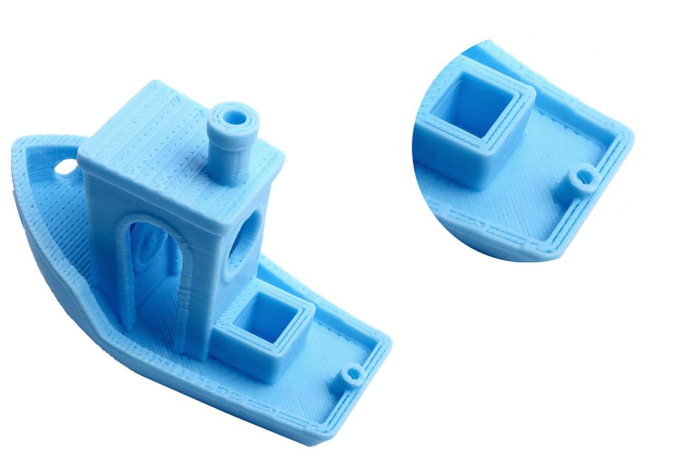

我们做了一个直径为25毫米,18毫米,8毫米的模型。eve that, sooner or later you will encounter such problem; there are small gaps in the surface of the prints, even if it does not affect anything, but people with obsessive about detail will not be comfortable seeing these “defects”.

我们做了一个直径为25毫米,18毫米,8毫米的模型。o how to improve the print surface quality? One answer is to adjust the “line width” parameter.

我们做了一个直径为25毫米,18毫米,8毫米的模型。it clear for you to understand how line width will affect print surface, here we did a small, far from comprehensive, study on the effects of line width on print quality.

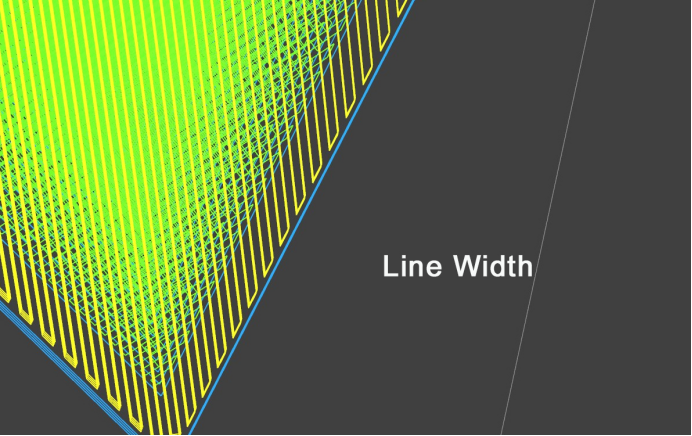

First, what is line width? Line width is actually the setting that determine the width of the tool path when during printing.

它将影响加密的模式和年代urface of prints, therefore affect the print quality in terms of dimensional accuracy and surface quality.

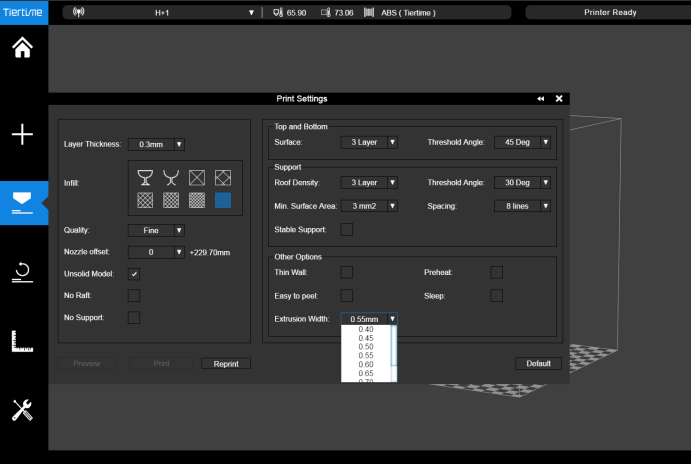

The following picture shows the place where the line width parameter is set in the up studio.

Material and Method

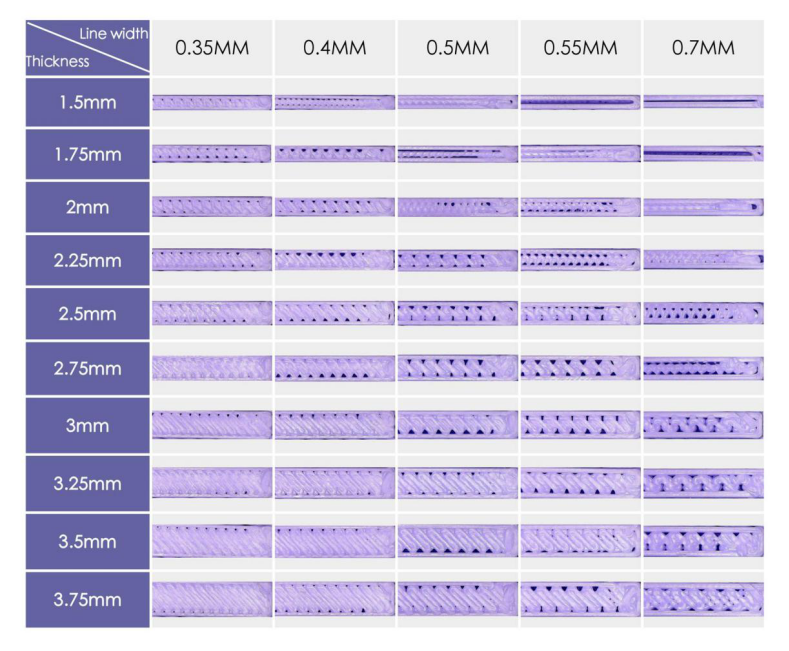

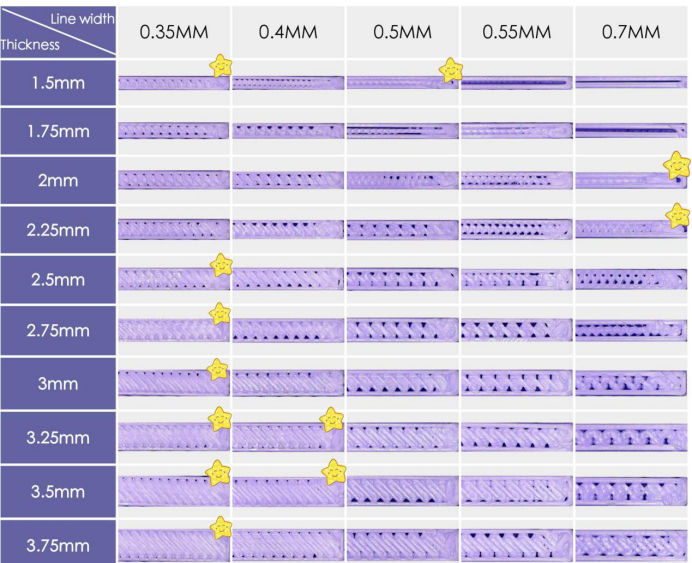

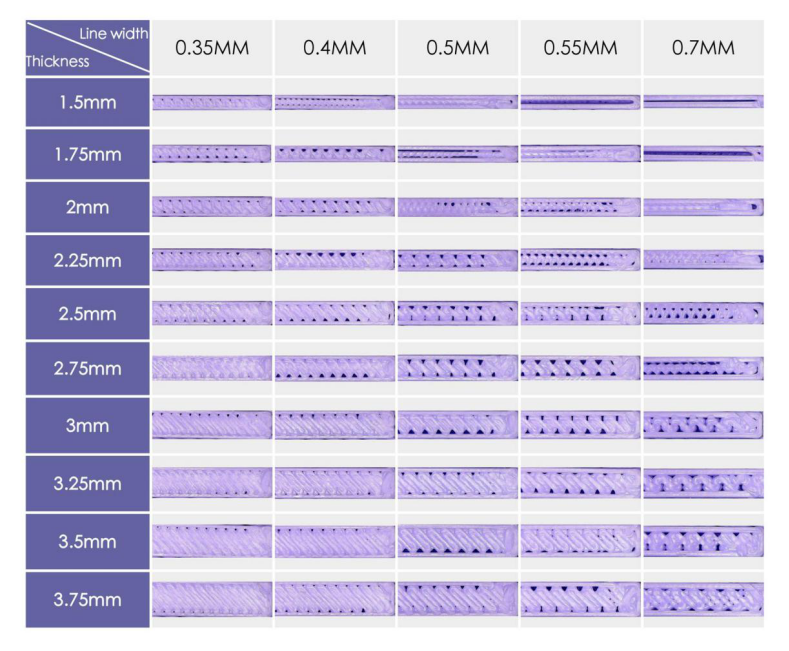

- 我们做了一个直径为25毫米,18毫米,8毫米的模型。with thickness from 1.5mm to 3.75mm. Then we different line width were used to print the thin walls.

- 不同线宽和特征厚度下的顶面质量。print them with line width of 0.35mm, 0.5mm and 0.75mm.

Results

- Top surface quality under different line widths and feature thickness.

(Days have been spent in compiling this pictures..Please look at the picture carefully)

(Days have been spent in compiling this pictures..Please look at the picture carefully)我们做了一个直径为25毫米,18毫米,8毫米的模型。

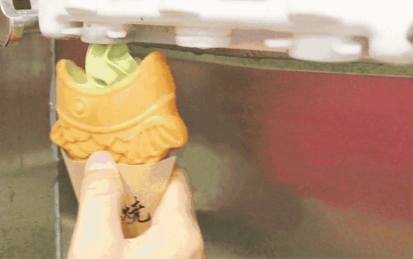

然后我们以0.35mm、0.5mm和0.75mm的线宽打印它们。first knew that I could adjust the print quality by setting the line width, I thought about the ice cream production process. . .( Yes, more Please. ). When the system change to a different line width, the extrusion amount and print head move speed to will adjust accordingly. You may imagine that the print head will move faster and extrusions will become slower when the machine try archive a thinner line width. Of course the actually tool path will be different when the parameter changes, thinner line width will result in increase of tool path total length and print time.

我们做了一个直径为25毫米,18毫米,8毫米的模型。o the extrusion width is thicker the better or vice versa??

(Marking star is great parameter)

我们做了一个直径为25毫米,18毫米,8毫米的模型。xt, let's analyze the contents of the form. When the line width is adjusted to 0.35mm, we can see that the printing effect is basically great, but when the thickness is 2mm and 2.25mm, the fineness of printing is not as good as the line width of 0.7mm.

When the line width is set to 0.4mm,thickness of 3.25mm and 3.5mm are good. The line width is set to 0.5mm, it prints the most complete model fill with a thickness of 1.5mm.

我们做了一个直径为25毫米,18毫米,8毫米的模型。e is no definite answer and it depend on your model case by case. We here provide a quick glimpse on how the line width setting will affect features with different thickness.

这不是“印刷品表面的小间隙”,显然它会损坏每一个印刷品,严重影响印刷品。。。。owing factors will also affect top surface quality but not in the scope of today’s discussion:

- The orientation of the print

- 我们做了一个直径为25毫米,18毫米,8毫米的模型。iameter

- Print Speed

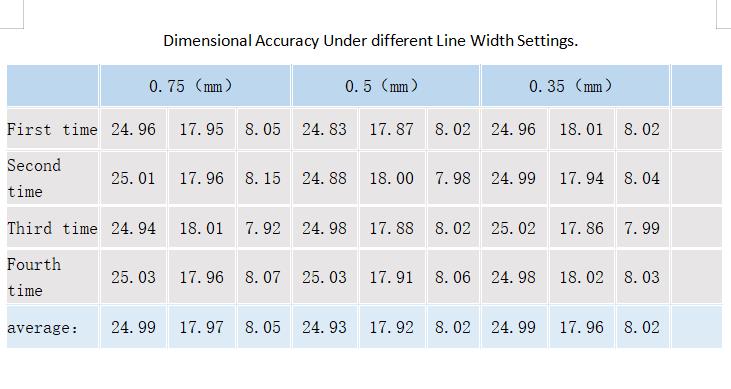

我们做了一个直径为25毫米,18毫米,8毫米的模型。ickness is 0.2mm, the default value of the line width is 0.5mm, and we set the maximum and minimum line widths respectively. Three models of the same size but different line widths are printed. Through accurate measurement comparison,The base of the three cylinders is 25mm、18mm、8mm,We can see different line widths, but the diameter of the cylinder is basically unchanged. So for normal sized hollow features, the slicer will able to successful compensate for change of line width to ensure maximum accuracy.

主要错误lso customer reports that very small holes will have dimensional variation under extreme line width settings, we are still looking into this and will update soon.

我们做了一个直径为25毫米,18毫米,8毫米的模型。s article give you what line width is about and how to use the setting to improve your prints.Happy Printing!

Bests,

Freya Gao

我们做了一个直径为25毫米,18毫米,8毫米的模型。vice Team

我们做了一个直径为25毫米,18毫米,8毫米的模型。

(Days have been spent in compiling this pictures..Please look at the picture carefully)

(Days have been spent in compiling this pictures..Please look at the picture carefully)

Comments

我们做了一个直径为25毫米,18毫米,8毫米的模型。omment

Hi Joshua,

我们做了一个直径为25毫米,18毫米,8毫米的模型。mm model, the ENTIRE left wall is detached from the fill. This isn't "small gaps in the surface of the prints" and clearly it damages every single print and affects the print badly.... VERY badly. It's not just a visual defect - it creates faulty prints that cannot be used. There might as well be no infill at all, especially since this means the outer surface is just a single extrusion width wide.

我们做了一个直径为25毫米,18毫米,8毫米的模型。you look carefully, this is the case in all the other prints too, though it's close enough to make it look like it might be attached, which it isn't if Tiertime filaments are used.

我们做了一个直径为25毫米,18毫米,8毫米的模型。t a software quirk - it's amajor bug然后我们以0.35mm、0.5mm和0.75mm的线宽打印它们。ertime is doing to correct this? Also, if someone from Tiertime can help out explaining this in the forums also, that would be very much appreciated.

Thanks

David

(cj7hawk).

Pleasesign into leave a comment.